Home

/

Products

Products

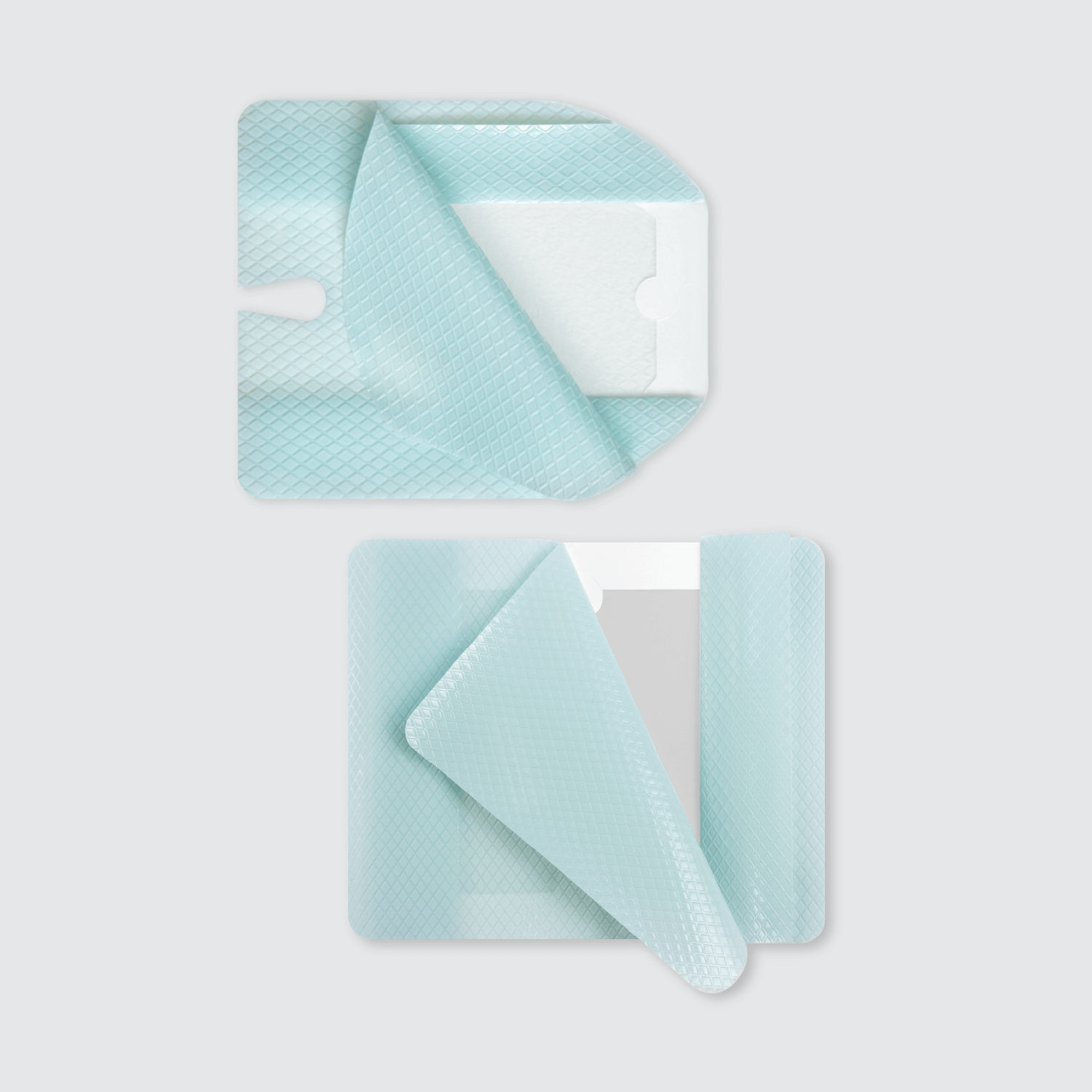

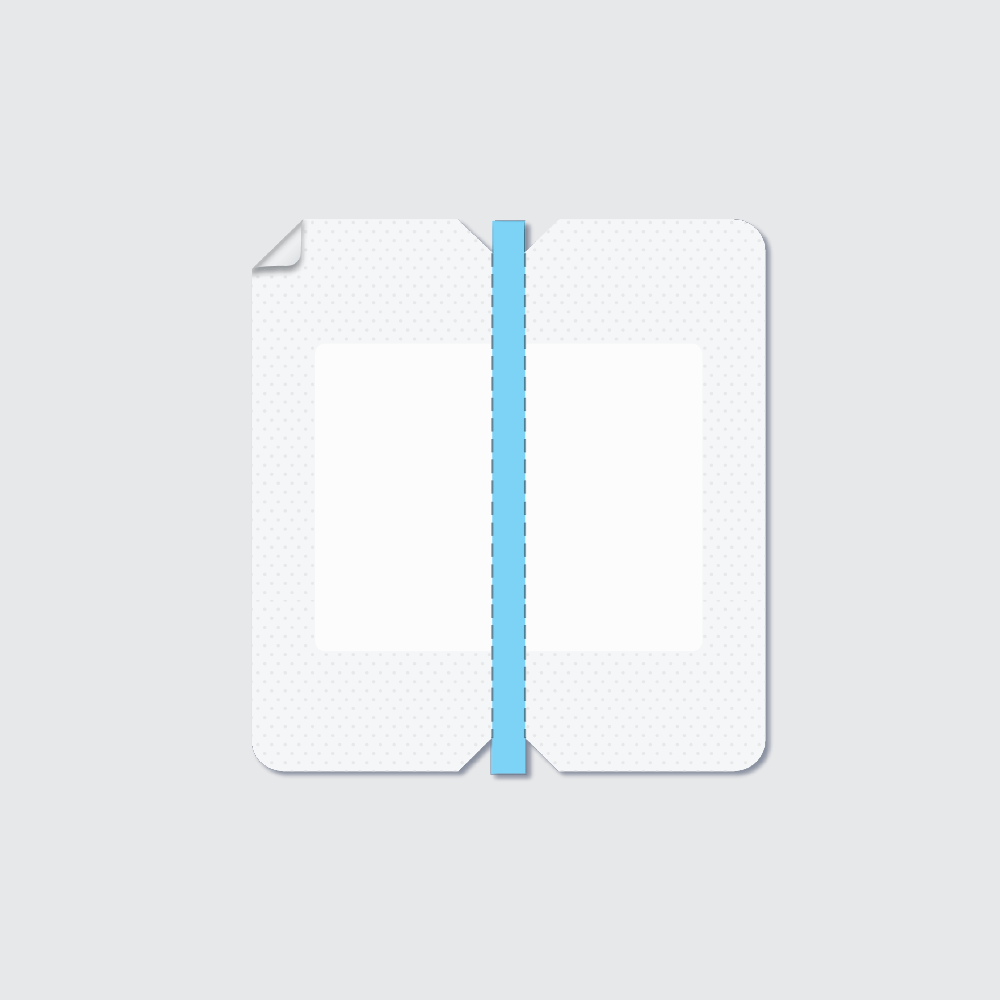

Discover our industry-leading collection of soft-silicone and dual-antimicrobial dressings, each uniquely engineered for comfort and effectiveness. Explore our I.V. hub and line-to-line connection barrier and range of wound solutions including silicone, collagen foam, alginate, and hydrocolloid dressings – all designed to meet the diverse needs of patient care.

Brands

Product Type

Featured Products